Service Hotline:+86 755-27717935 / 27229158 CN

|

|

|

|

|

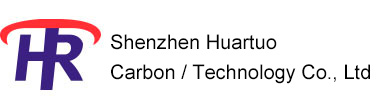

Step 1 : material

3D curved glass Rewriting graphite mold on the material demanding, select high-quality special graphite material, can improve die life, reduce manufacturing costs, reduce glass deformation, cracks, burr and other bad quality problems, but also provide the glass processing and polishing quality And efficiency.

Keywords: Japan's East China Sea carbon HK-75, more materials can consult the staff |

|

|

|

|

|

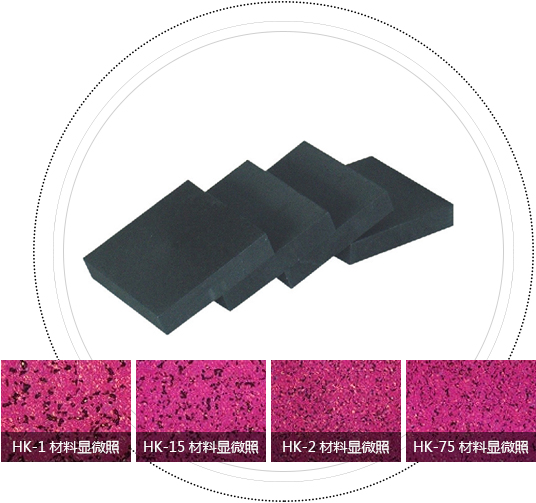

Step 2 : Mold design

Curved face bending mold design directly affects the finished glass bending rate. Keywords:

Cost: fully consider the customer finished factors, "tailored"

|

? ? ? ? ? ? ? ? ? ? |

|

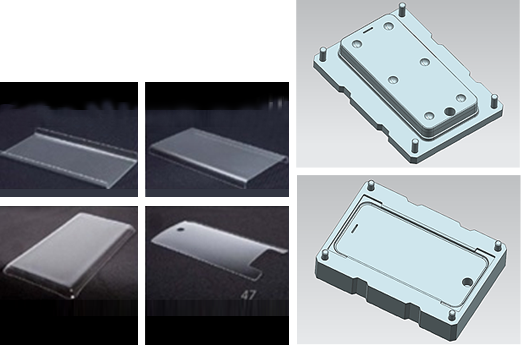

Step 3 : CNC machining

We use high-precision graphite special processing machine tools, auxiliary dedicated graphite vacuum suction cups and special graphite processing tools to protect the customer's hot-bending graphite mold processing accuracy.

Keywords:

Special: all processing processes and accessories processing hardware in a special form.

High precision: the highest surface processing accuracy of up to 0.015mm, plane machining accuracy of 0.005mm.

Efficiency: continuously improve the processing process to improve the efficiency of mold processing, we use semi-automatic production process, the latter part of the preparation of fully automated robot to further improve production efficiency.

Capacity customization: At present, we can meet the highest 40 processing center production, monthly products up to 5000-6000 sets of graphite Rewan die, the customer can customize the machine program.

Processing program customization: We can provide a variety of processing options for customers to choose, according to their own custom processing process, long-term supply can be adjusted.

|

? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? |

Step 4 :?Mold polishing and post-processing

Now the peers always polish surface of the Roving Graphite Moldby hand to reduce the accuracy of the back-end sweep.Advantages: It is easy to handle for various shapes, with almost no blind spots; Disadvantage: higher quality of staff, and lower efficiency, batch is not high, no uniform standards;

Keywords:

Professional: Professinal team to garantee the accuracy of mold polishing . Capacity:? can be guaranteed with the production and processing synchronization. |

|

|

|

|

|

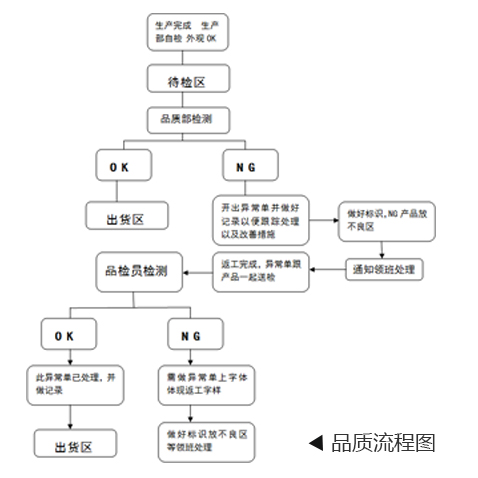

Step 5 :Mold quality inspection

We use precision coordinate measuring machine mold face to protect the detection accuracy, each shipment with three yuan test report.

Keywords: Accuracy: our testing equipment on a regular basis to do third-party calibration to ensure long-term detection accuracy.Timeliness: Each set of graphite molds must be tested on site. Authenticity: Each batch of products with three yuan test report.

|

? ? ? ? ? ? ? ? ? ? ? ? ? ?? |

|

|

|

|

|

|

? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? |

Step 6 :After-sale service & technology support

Curved glass mold bending forming for the surface of the glass process an important process, but also the industry is an important technical threshold. We have a professional after-sales technical team to solve the problems in the customer's hot-bending graphite mold.

Keywords:

|

Official WeChat